General Engine and Prop Resources

Interchangeability of Marine Diesel Engines with Farm and Industrial Engines

Shibaura Diesels – (Perkins and Volvo)

Link to Cruisers Forum Engine Interchangeability

Lots More Interchangeability of Engines Here

Sailnet Thread about Volvo and Yanmar Engines

Shibaura Diesels: To me, this is what makes sense, to the best of my research. Volvo and Perkins engines are made by Shibaura. They are the base for the Volvo 2010, 2020, & 2030 series as well as the Perkins 100, M20,M30. Apparently Ford bought its small diesel tractor engines back in the 1990’s from Shibaura as well, and then sold its tractor division to New Holland – whose dealers are common in N America. Apparently the M30 Perkins is used in the Ford New Holland 1310. Many Massey Ferguson tractors use “Perkins” diesels. Have not confirmed the model numbers of these tractors.

Perkins-M20-25-30-35 Operating Instructions

Perkins 100 Series Workshop Manual

Kubota Diesels – Universal – Beta – Nanni

Universal Marine Engine Schematics

Sailnet Thread about Universal Diesel Engine Interchange Parts

Sailnet Thread about Universal Fuel Injector Interchange

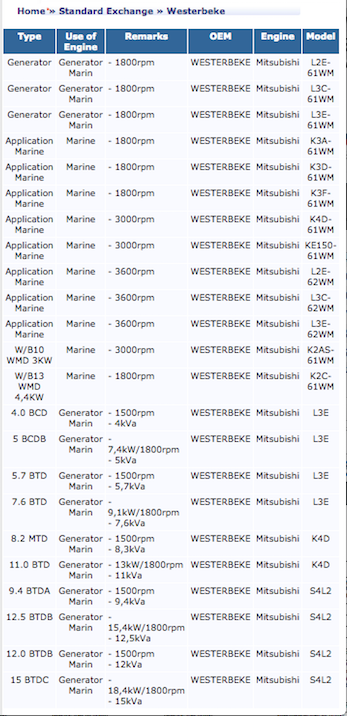

Mitsubishi Diesels – Westerbeke

Cruisers Forum Discussion with the Following Information:

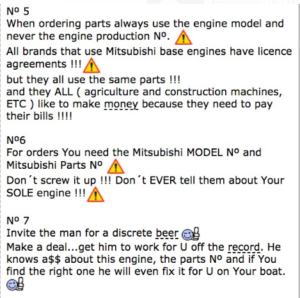

Mitsubishi Diesel Engine Interchange

And then this how to use the above link:

Marine diesels are based upon engines used in other applications. Except for the Kubota based marine engines, which give you the part number interchange so you can buy parts at your local tractor dealer, the marine diesels attempt to hide what their engines are based on so you have to pay the “Yacht Surcharge” which can be considerable. Westerbeke engines are based on Mitsubishi. Now often if you tell your engine dealer that your engine is in a boat they won’t sell you parts. So determine where your marine engine is used in industry and buy parts based upon the block number. Some Westerbeke parts are supposedly modified slightly from the Mitsubishi parts so that they are not a direct fit. Be careful!

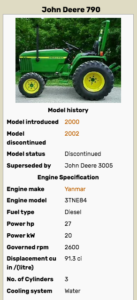

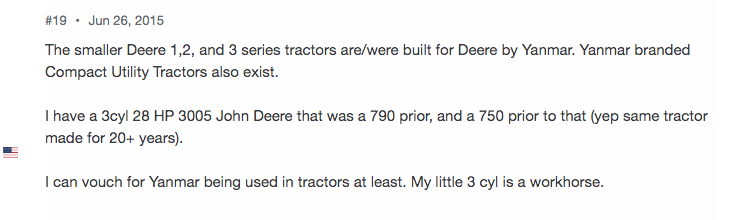

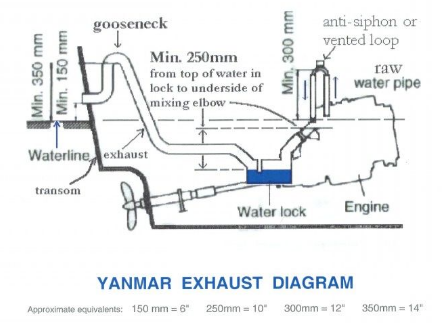

Yanmar Diesels – Manuals

Yanmar supplies diesels to John Deere tractor and ThermoKing for refrigerated trucks and trailers.

Yanmar Tech Bulletin – Gearbox Position when Sailing?

Operation Manual – Yanmar GM Series

Shop and Service Manual – 3GM30

Volvo Penta

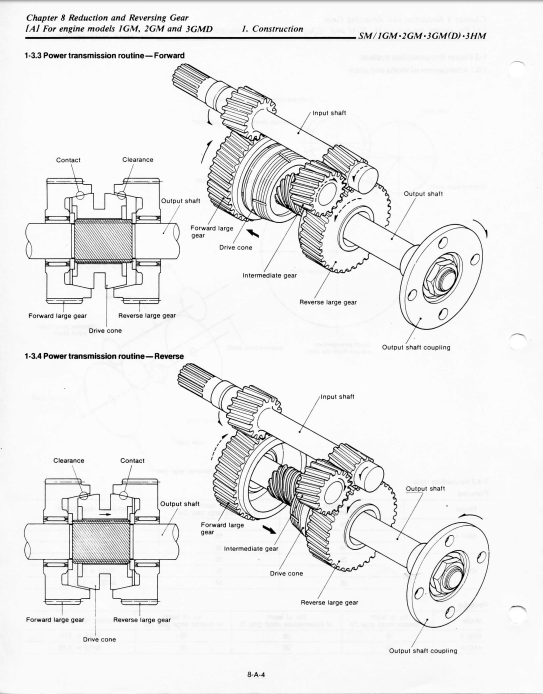

Kanzaki Transmission

Repair Manual – Kanzaki zf_gearbox

Kanzaki Transmission Service Manual

Transmission Schematic

Tony’s Tips – 35 years of experience with marine engines and hydraulic steering systems

Lancing Marine – Marinizing Diesel Engines

Diesel Water Vapor Trap – i made this for less than $5. There are commercial ones made for much more. It is a major step to the solution to bugs in diesel fuel, clogged fuel filters, and clogged injectors. Diesel fuel will NOT grow bugs (bacteria) if it has no water in it. End of discussion. The water gets in there in three ways: 1. the fill cap is not watertight 2. there is water in the diesel, ie: contaminated fuel 3. water vapor thru the vent. Remember that there is a lot of moisture in a marine environment and every fuel tank has a vent. This filter stops the water vapor from getting to the diesel thru the vent. IT HAS NOTHING TO DO WITH HOW FULL OR EMPTY THE TANK IS – water will not condense on the walls of the tank if the vapor can’t get there in the first place. The tube is filled with something like this: Indicating silica gel, which then is dried out in the oven or frying pan when the color changes, indicating that the gel is saturated with moisture. This silica gel has many other uses among them are keeping moisture away from the electronics

The Real Causes of Prop Walk

There are many contradictions out there (i.e., it is caused by differential “digging in” between the top and bottom of the prop, or it’s caused by the angle of the prop shaft.) The Castle Marine website has an FAQ page that includes the BEST explanation of prop walk that I’ve found anywhere – it makes sense and includes easy to understand diagrams.

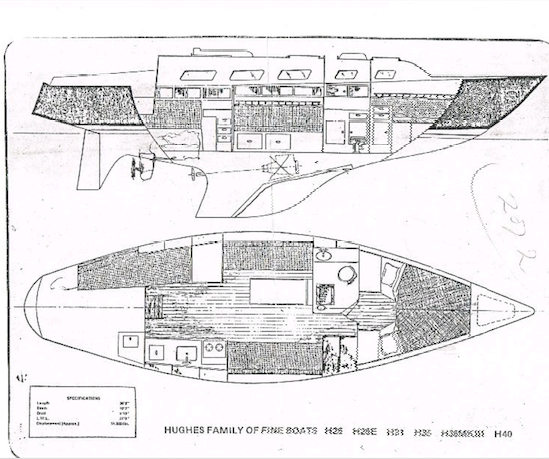

The bottom line is that with our Hughes 38s that have the shaft drive and the engine in the bilge, we should expect to have minimal prop walk compared to most boats with shaft drive, because the angle of the shaft is closer to horizontal, AND the prop is close to the center of the boat. These two factors combined make for little prop walk. Problem? Many docking plans (for instance Here) make use of prop walk to move the stern of the boat against the wind. Hmmmm

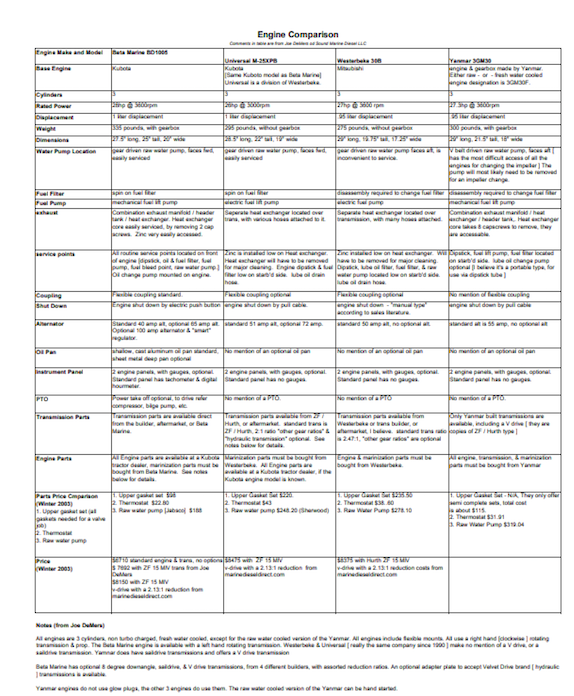

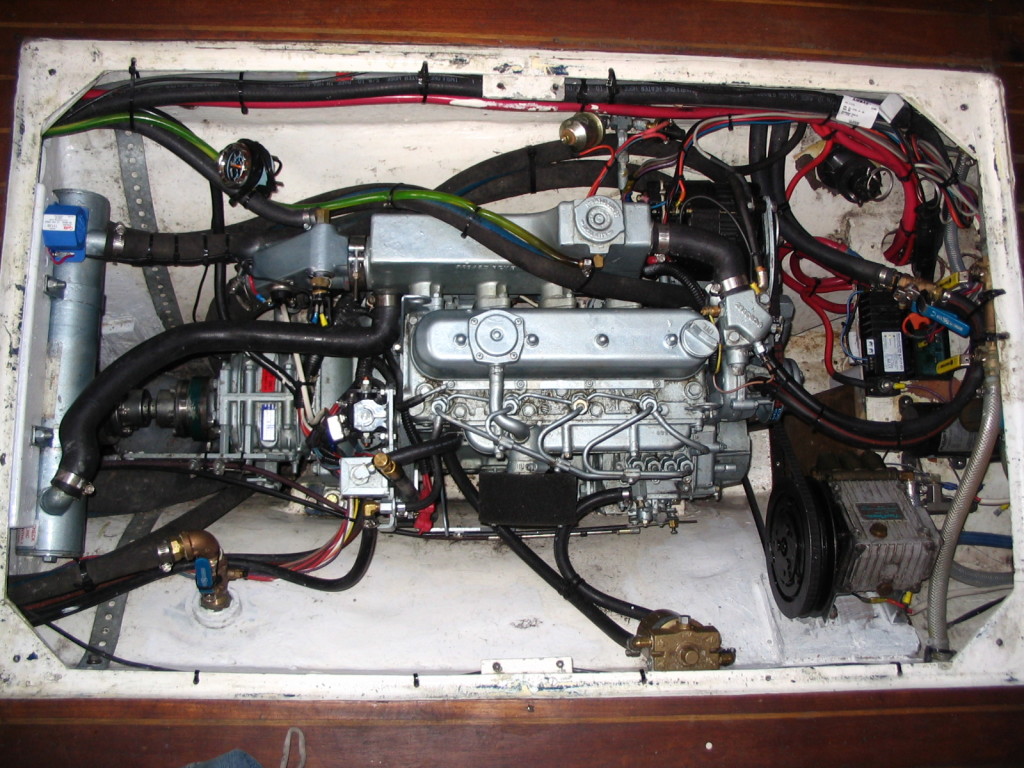

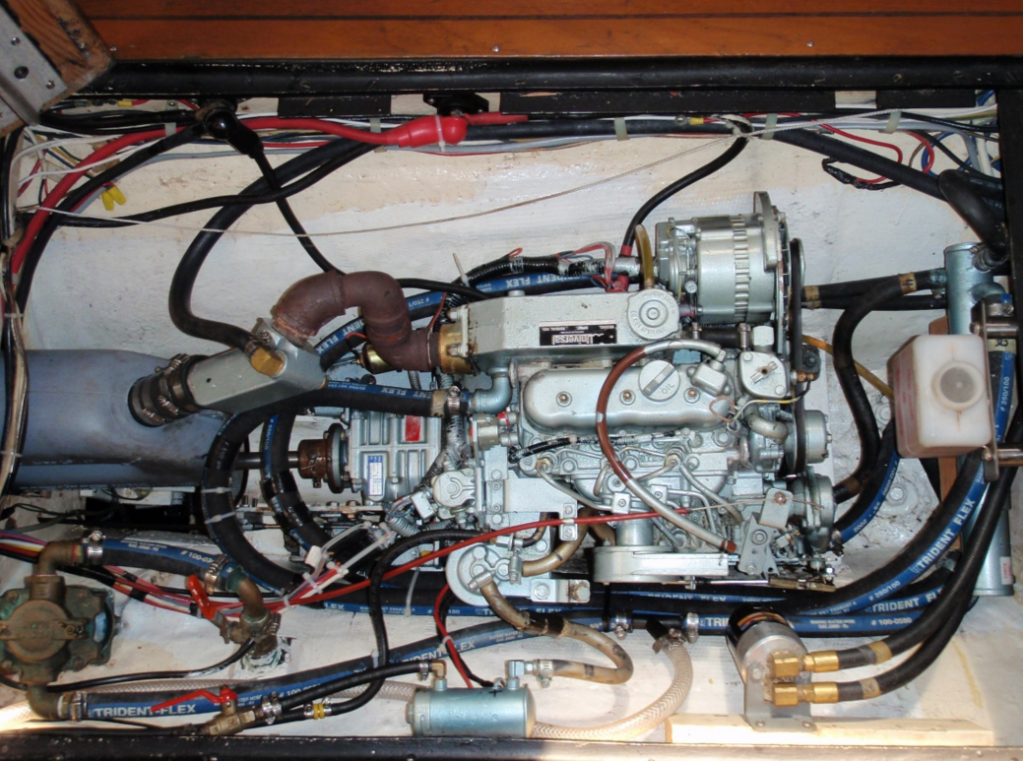

Universal 30hp in H38 SV Water Lily

SV Globi with Nanni (Kubota) 21 Hp – note the clean installation. Raw water cooled.

An excerpt of an email from Robert Hess:

Universal 20hp in H38 SV Verdia

|

The owner of the engine above writes “The 20hp. engine cruises along just fine at 5.5 kn. at 2500 rpm with modified Campbell sailer prop. Averaging about 1/3 to 1/2 gall. per hr. Top speed under power is 7 kn. With 4 jerry cans I have about 500 mile range.”

|

Yanmar 3GM30

Yanmar 3GM30 engine seems to come with the Kanzaki KM3P transmission in either 2.62:1 or 2.21:1 gear ratios.

Atomic 4

Atomic 4 on SV Wiskejak – The One Dollar Boat

Rob Hess on the Atomic 4 – Frequently Asked Questions

Indego Electronic Ignition for Atomic 4

Atomic-4 Transmission Service Manual

Atomic 4 Repair and Maintenance

Atomic 4 Cleaning From Good Old Boat

Atomic 4 Common Parts Interchange

Atomic 4 from Pearson Vanguard Website

Atomic 4 Manual from Tartan 34 Website

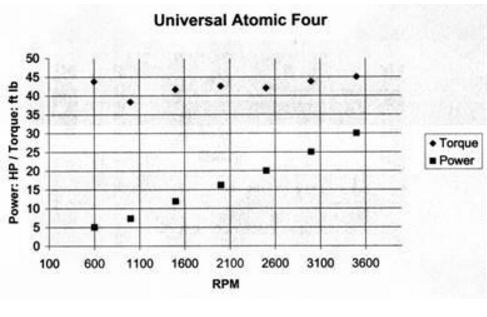

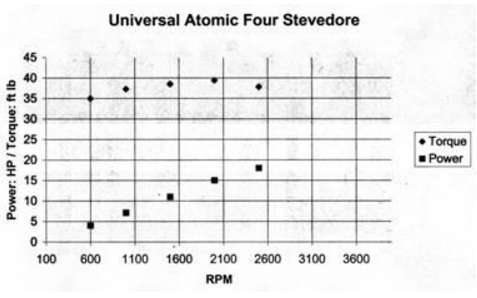

Atomic 4 Torque curves – courtesy of Robert Hess

Questions: Since the engine is in the bilge for the Yanmar and the Atomic 4, the combustion air for the engine is reportedly to be vented through the mast. Does anybody know for sure?

The vent for the gasoline or diesel tank is reportedly to be through a stantion. Does anybody know for sure?

Volvo Saildrive

Some have stated that this was an option at one time. I have seen three MKIII’s with Volvo Saildrive. One owner claims his (1980) was installed at the factory and that he has the original factory manual with a Volvo-Penta MD11C 2 cylinder diesel Saildrive. Another source claims that the Volvo-Penta engine is an MD17C. Engine is freshwater cooled by way of a heat exchanger for onboard domestic hot water.

Saildrive Plan I suspect that the saildrive wasn’t approved by S&S: note the quality of the changes in the drawing and the Hughes name at the bottom.

Volvo Penta Saildrive Beneath Companionway

Propeller

A Test of Props from YachtingMonthly

A Yachting Monthly discussion and testing of folding and feathering props.

Courtesy of Rob Hess

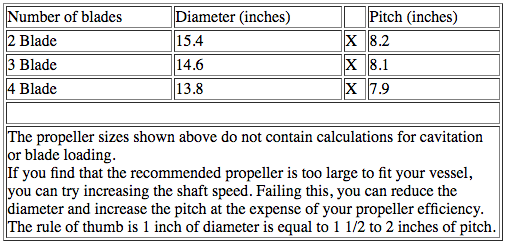

One owner has mated a 14×9 2-bladed fixed propeller to the A-4 motor with the 2:1 reduction gear. He reports that the 15×10 3-bladed prop was too much prop for the A-4 engine.

Another owner has a Universal diesel (Kubota) 20hp with a 14×6 Campbell Sailor 3-bladed prop (the previous 15×8 was overpropped for this motor)

A Beta diesel dealer (a Kubota based engine) recommends the Beta 25 with a 2:1 transmission, stating that propped correctly it will consume 1 US gallon in 3 hours at cruising RPM. He states that the Beta 30 will create too many installation issues. His prop calculator gives optimum results of 14×9 or 13×10 3-bladed Michigan Wheel MP3 or DJ355.

One owner reports: “There’s very little exposed shaft between the cutlass bearing and the prop. This only leaves room for one donut zinc anode, which may or may not last the year depending on local conditions, etc.”

An email from Robert Hess:

Some… don’t understand the difference in horsepower between a direct drive Atomic Four (no reduction gear, or a 1:1 V drive) and an Atomic Four with a 2:1 Paragon reduction gear (or 2:1 V drive).

Many sailboat owners also don’t understand that horsepower is a function of torque x rpm, so the propeller can limit horsepower if it doesn’t let the engine get up to its rated rpm (ie Atomic Four: 30 hp @ 3,500 rpm). They think that a bigger prop will let the engine turn slower at cruise speed, but what it actually does (besides lugging/damaging the engine) is lower the maximum rpm and therefore lower the maximum horsepower available from the engine.

A displacement hull sailboat cannot be driven past its calculated hull speed no matter how much horsepower is used. If it is towed past its calculated hull speed by a bigger boat it will start to zig-zag all over the place and either the tow ring or bollard will rip out of the deck, or the boat will suddenly dive under the water. That’s why whenever a sailboat is towed by a larger boat the owner should warn the tow boat captain not to exceed the smaller boat hull speed (ie around 8 kn for a Hughes 38), and should stand ready with an axe to cut the towline if the tow boat does suddenly start to go too fast (which often happens).

The maximum rpm the propeller on a displacement hull sailboat can turn before propeller cavitation becomes a problem is around 2,000 rpm.

If a direct drive (1:1) gear ratio Atomic Four engine (ie without a 2:1 reduction gear) is fitted it can only be revved up to 2,000 rpm. Over that the prop will cavitate badly. That means that the actual horsepower the engine is generating is limited to around 14 hp.

which is all the power needed for smaller sailboats, so many smaller boats have a direct drive Atomic Four installed, with a prop that limits the rpm to around 1,600 to 2,000 rpm.

If an Atomic Four with a 2:1 reduction gear (or 2:1 V drive) is installed, as in the Hughes 38, then the full rated rpm (intermittent rating, which means it can be used for a maximum of 10 minutes to get out of the way of a big ship) 3,500 rpm of the engine can be used because the 2:1 gear ratio will drop the propeller rpm to a maximum of 1,750 rpm, and so the engine will be able to generate its rated full 30 hp without the prop cavitating.

Rob

The above table is from the VicProp Calculator and is for a Hughes 38 -a Yanmar 3GM30 with 2.21 reduction gear.

Another email from Rob Hess

Three Panel Engine Access

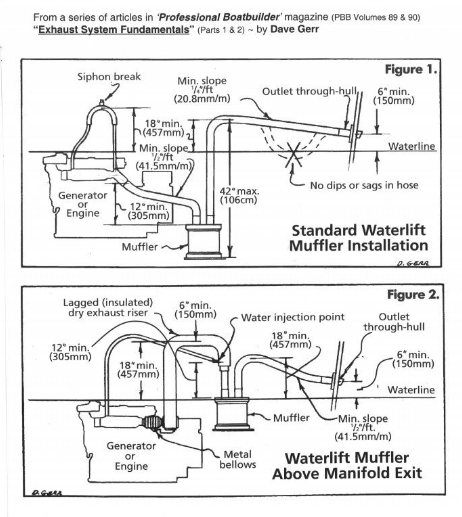

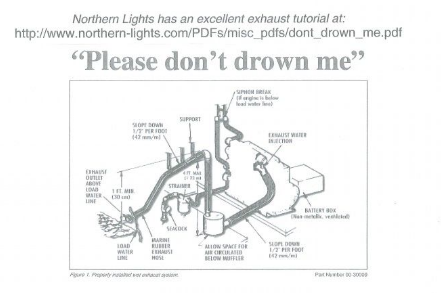

Wet Exhaust

SV Dreamwalker 15 hp 2 Cylinder Yanmar(?)

Email from Robert Hess: Considerations for Repowering the Atomic 4

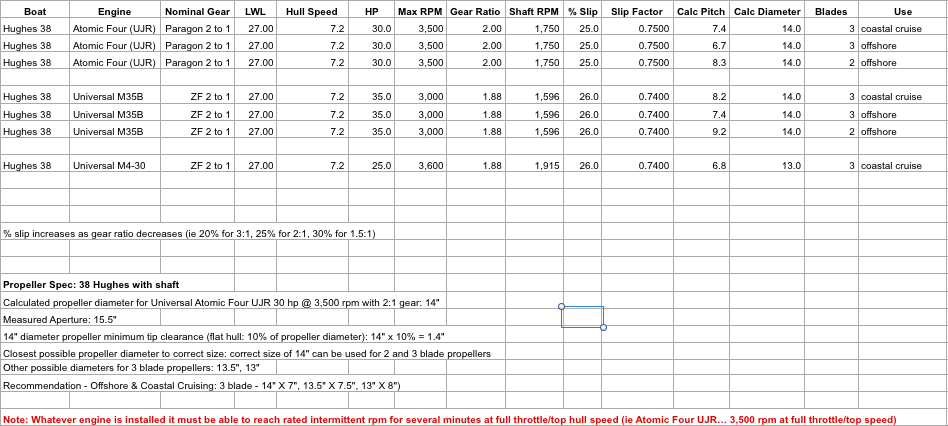

The standard Hughes 38 was available with a 30 hp (at 3,500 rpm) Universal Atomic Four gasoline engine fitted with a 2.04:1 Paragon reduction gear, or a Volvo Penta MD-17 diesel engine with a Volvo S-120 saildrive. I’m pretty sure the saildrive had a 2:1 reduction gear, because if the reduction gear was a 3:1 the large diameter prop required wouldn’t have fit (see below).

Many people don’t understand that repowering a sailboat involves calculating the optimum engine power, optimum gear ratio, and correct propeller diameter before ordering an engine, reverse gear, or propeller. Often the old propeller must be replaced, unless the new engine is very similar in power to the old one. The limiting factor on the Hughes 38 (and many other sailboats originally designed to be powered by a Universal Atomic Four… in larger boats usually an Atomic Four with a 2:1 reduction gear) is the distance between the centreline of the propeller shaft and the hull, directly over the propeller location on the shaft. This distance – doubled to give diameter, less 10% of propeller diameter for tip clearance, is the maximum propeller diameter that can be fitted, and the propeller pitch, gearbox ratio, engine rated maximum rpm must all be based on that. In most cases the larger the propeller diameter the better the thrust because a larger propeller can be turned slower, and the slower the propeller turns the less the slippage and wasted power. It is usually assumed that optimum pitch is slightly less to slightly greater than the diameter, ie 14″ diameter X 12″ to 16″ pitch will work OK. If the calculated pitch is outside that parameter then the propeller diameter, gearbox ratio, or engine rated rpm are not correct. So, the first thing to do when repowering is to measure the propeller “aperture” (as a diameter) and deduct enough from that get the maximum propeller diameter… leaving an extra space for 10% tip clearance. That number will be used by the engine supplier and the propeller supplier to calculate the correct horsepower, gear ratio, and propeller pitch for the new engine installation. In the case of the Hughes 38 another consideration is engine height so the engine will fit under the saloon floor without raising it (see below).

Once the repower is finished the boat should be sea-trialled to verify that the engine can reach rated rpm at full throttle/top speed (ie the rated rpm of a Universal M35-B is 3,000 rpm, so when the boat is run at top speed the tachometer must read 3,000 rpm. No matter which engine is used, many boats are over-propped and will not reach rated rpm… this causes engine lugging, which causes overheating and all sorts of mechanical problems… often the weak link is not the engine, but is the gearbox clutches, which will fail prematurely from “overload” (which is what the manufacturer will call it when he denies the warranty claim).

Because the Hughes 38s standard Atomic 4 engine was mounted below the salon floor (if the optional Volvo Penta saildrive was fitted it was installed below the companionway stairs) repowering with a diesel must be carefully planned so that the new engine will still fit without having to modify the salon floor. It is very common to see Hughes 38 boats which have been repowered with an engine that doesn’t fit, and which required the salon floor to be either raised or notched, creating a tripping hazard (ie the Perkins installed in “Wild Card” was too high, and so the salon floor has a 3″ high box around the engine). The Universal M35-B engine and 2:1 ZF-10 gear fitted to Water Lily just fit underneath the floor only after I cut away the front of the hatch at the front of the engine. (Universal diesels are marinized Kubota diesels.)

The other problem with repowering is that the Hughes 38 with an Atomic Four had a heavy two-part water-jacketed exhaust pipe running from the engine to the stern under the salon floor. By the time repowering takes place it will require replacement to ensure sea water doesn’t drip through a corroded hole in the inner pipe and flow back into the new engine… which will destroy it. Most repowers include replacing the water-jacketed exhaust with a water-lock muffler, usually mounted underneath the gearbox and/or propeller shaft, and rubber exhaust hose, rather than fabricating another heavy jacketed exhaust pipe. If a water-lock muffler is installed an anti-siphon valve must be installed in the water hose from the heat exchanger to the exhaust elbow water injection fitting at the same time. Because the exhaust hose run is so long due to the centre-mounted engine, the hose diameter should be as large as possible to reduce back pressure. After the new engine has been installed the exhaust back pressure should be checked… it must not exceed 1.5 psi at full load.

Water Lily also has an Aqua-drive constant-velocity joint drive with the thrust taken by a heavy plate glassed to the hull, and different engine mounts than the ones supplied with the new engine by Universal in order to get the engine to fit. I also had to grind some of the fibreglass away from the inside of the hull and cut the ends off the engine mount supports.

Also, Water Lily has an optional pulley installed on the end of the crankshaft which is used to drive a high-pressure water pump for the Aqua-Drive water maker. Some people use the optional pulley to drive a large water pump which can be used as an emergency bilge pump and a high volume fire fighting pump.

There are lots of other issues with repowering, but this is an introduction to some of the main ones.

Rob

And another email:

Some… don’t understand the difference in horsepower between a direct drive Atomic Four (no reduction gear, or a 1:1 V drive) and an Atomic Four with a 2:1 Paragon reduction gear (or 2:1 V drive).

Many sailboat owners also don’t understand that horsepower is a function of torque X rpm, so the propeller can limit horsepower if it doesn’t let the engine get up to its rated rpm (ie Atomic Four: 30 hp @ 3,500 rpm). They think that a bigger prop will let the engine turn slower at cruise speed, but what it actually does (besides lugging/damaging the engine) is lower the maximum rpm and therefore lower the maximum horsepower available from the engine.

A displacement hull boat (ie sailboat) cannot be driven past its calculated hull speed no matter how much horsepower is used. If it is towed past its calculated hull speed by a bigger boat it will start to zig-zag all over the place and either the tow ring or bollard will rip out of the deck, or the boat will suddenly dive under the water. That’s why whenever a sailboat is towed by a larger boat the owner should warn the tow boat captain not to exceed the smaller boat hull speed (ie around 8 kn for a Hughes 38), and should stand ready with an axe to cut the towline if the tow boat does suddenly start to go too fast (which often happens).

The maximum rpm the propeller on a displacement hull boat (ie sailboat) can turn before propeller cavitation becomes a problem is around 2,000 rpm.

If a direct drive (1:1) gear ratio Atomic Four engine (ie without a 2:1 reduction gear) is fitted it can only be revved up to 2,000 rpm. Over that the prop will cavitate badly. That means that the actual horsepower the engine is generating is limited to around 14 hp.

14 hp is all the power needed for smaller sailboats, so many smaller boats have a direct drive Atomic Four installed, with a prop that limits the rpm to around 1,600 to 2,000 rpm. (Some smaller boats have a V drive, but the V drive ratio is 1:1, ie the Hughes 25 and other smaller models.)

If an Atomic Four with a 2:1 reduction gear (or 2:1 V drive) is installed, as in the Hughes 38, then the full rated rpm (intermittent rating, which means it can be used for a maximum of 10 minutes to get out of the way of a big ship) 3,500 rpm of the engine can be used because the 2:1 gear ratio will drop the propeller rpm to a maximum of 1,750 rpm, and so the engine will be able to generate its rated full 30 hp without the prop cavitating.

Rob

Thrust Bearings

One of the best upgrades that you can do for your engine system. The thrust bearing eliminates problems with alignment of the engine and shaft. It makes the engine a lot quieter as much noise is transmitted thru the vibrating shaft. If you hit an obstruction while underway, the thrust bearing will protect your transmission from damage.

Aqua Drive – the top of the line (?) in marine thrust bearings